Garaga G-5000, G-5200 and G-5138 Commercial Doors

The ones that adapt to varied work environments

The Garaga G-5000, G-5200 and G-5138 are industrial garage doors pre-painted galvanized steel for industrial and commercial use that offers all the benefits of a standard garage door, PLUS a superior insulation factor higher and a system of ironwork which allows a flawless opening and closing of the door.

- Steel

- Thickness: 1 ¾”

- 9 colors

- Polyurethane sandwich door

- R‑16 insulation

- Model: Grooved

INSULATION OPTIONS

G-5138: R‑12, Thickness: 1 3⁄8″

G-5200: R‑18, Thickness: 2″

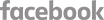

A) High-pressure injected polyurethane

- Stronger and more energy-efficient insulation

- Solidly bonded to the steel sheets providing a section that is resistant to flexion.

B) Sealed thermo-pane windows

- Optimize insulation and reduce seal failures with galvanized steel spacer technology

- Ensure a long lasting and refined appearance with one-piece molded polypropylene window frame.

C) InterlokTM triple-contact joints

- Sections are strengthened by 2 steel walls joined together with mechanical interlocking joints which are more solid than just two bonded walls.

- Mechanical thermal breaks which are more efficient compared to thermal breaks made with glue.

- Triple-contact joints provide 2 times more weathertightness than those of the competition.

D) Metal reinforcement plates

- Provide stronger fastening for hinges and struts. These 14-gauge plates are 2 times thicker than 20-gauge plates used by other manufacturers.

E) Wood end blocks

- Provide a thermal break that is more effective than steel end caps which form a thermal bridge.

- Structural elements of the sections, the kiln-dried pine wood end blocks are installed at the outer ends of the section. They are stronger than insulation covered with a steel cap.

F) Lag screw system

- Provides much better fastening of the end hinges. The lag screws engage 8 threads into the wood, compared to a self-tapping screw going through a steel end cap engaging only about 2 or 3 threads.

1) Steel walls

- 26/26-gauge, G60 hot-dipped galvanized steel with five coats of protective finish.

- Baked-on polyester paint. Can be repainted.

- Woodgrain finish on both sides of the door.

- Same quality of corrosion-resistant steel for interior and exterior faces.

2) Insulated door with high-pressure injected polyurethane foam ensuring a high thermal-resistance rating and the solidity of a composite material.

- G‑5000: 1 ¾” (44.5 mm), R‑16 (RSI 2.8 or k= 0.357 W/m2K)

- G‑5138: 1 3⁄8″ (35 mm), R‑12 (RSI 2.1 or k= 0.476 W/m2K)

- G‑5200: 2″ (50 mm), R‑18 (RSI 3.2 or k= 0.313 W/m2K)

3) InterLokTM joints between each section:

- Mechanical joints ensure stronger sections with walls of each panel mechanically interlocked (not only bonded by the polyurethane).

- Mechanical thermal break avoids heat transfer between the interior and exterior walls of each section.

- Triple-contact joint prevents air infiltration.

4) U-shaped tubular bottom weatherstripping made of thermoplastic elastomer (TPE) ensures the weathertightness of the threshold. Remains flexible and watertight during cold weather, to -62°F (-52°C).

5) Wood end blocks made of kiln-dried pine (grade 4). With our lag screw system, ensure better fastening of the end hinges. They also provide a thermal break which prevents thermal bridging.

6) 14-gauge steel reinforcement plates placed inside the door for solidly attaching hinges and struts.

Door weight:

G-5000: 1.90 lb/ft2 (9.3 kg/m2)

G-5138: 1.75 lb/ft2 (8.5 kg/m2)

G-5200: 1.95 lb/ft2 (9.5 kg/m2)

MODEL

Grooved

SIZES (G-5000 and G-5200)

Width – In 1″ (25 mm) increments : From 4′ to 29’6″ (1.2 m to 9 m)

Height – In 3″ (76 mm) increments : From 6′ to 24′ (1.8 m to 7.3 m)

SIZES (G-5138)

Width – In 1″ (25 mm) increments : From 4′ to 18’2″ (1.2 m to 5.5 m)

Height – In 3″ (76 mm) increments : From 6′ to 18′ (1.8 m to 5.5 m)

- 10 years against any perforation of steel due to rust

- 10 years on the wood and blocks against cracking and rot

- 10 years against delamination of the steel skin from the polyurethane foam

- 1 year on other door components

- 10 years against seal defects on Standard windows

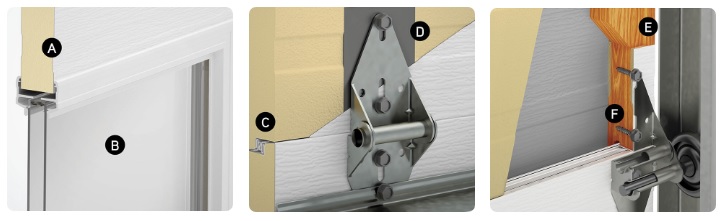

STANDARD

PREMIUM

Premium Colors: small additional fees apply.

The accuracy of colors on the website may vary depending on your screen settings. To see the true colors, please contact your local Garaga dealer for a sample.

STANDARD WINDOWS

Available for doors: G-5000, G-5138, G-5200

Sizes: 21″ x 13″ (533 mm x 330 mm)

Glass

- Thermopane windows: Clear, Satin, Wired, Tempered, Laminated or Tinted

- Single glass (3 mm): Clear, Satin, Tempered or Tinted

- Polycarbonate (3 mm): Single or Thermal (Sealed): Clear or Tinted

Frame colors: White, Desert Sand, Claystone, Dark Sand, Brown, Evergreen, Black and Charcoal.

OVAL WINDOWS

Available for door: G-5000

Sizes: 26″ x 13″ (660 mm x 330 mm)

Glass

- Polycarbonate only

Frame color: Black

G-4400 SECTIONS (FULL VISION)

Available for door: G-5000

All info about this product: See the G-4400 section

Glass

- Single pane: Clear, Satin, Tempered, Laminated or Tinted

- Sealed windows: Clear, Satin, Wired, Glue Chip, Low-e, Tempered, Laminated or Tinted

- Fluted polycarbonate: Clear or Bronze

- Single polycarbonate : Clear or Tinted

- Sealed polycarbonate (thermal): Clear

Frame colors: White, Black and Anodized

STEEL TRACKS

- 2” (50 mm), 13-gauge or 14-gauge

- 3” (76 mm), 12-gauge

HARDWARE SYSTEMS AND OPTIONS

Learn more about: